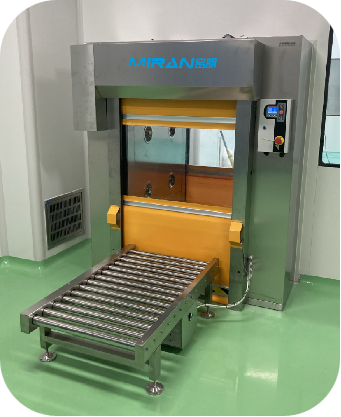

Detail:

Product introduction

The air shower transfer cabin is used for material transfer between clean and non clean areas to prevent unclean airflow from entering the advanced clean area. The air shower unit developed and designed by Miran is different from traditional air shower rooms in that it has functions such as clean airflow, automatic material transfer, and automatic induction opening of the air shower door. At the same time, the air shower room unit also serves as an airlock to prevent unpurified air from entering the clean area. It is an effective equipment for material transfer to prevent external air pollution of the clean area.

Product Model: MCT-ASU-01

Product Features:

1. Install a spray purification device in the work area to remove dust adhering to the surface of the packaging bag;

2. Automatic control, infrared sensing, automatic top air blowing and showering;

3. The blowing speed can reach 20m/s+/-20%;

4. There is a sensor in front of the door that senses the material and automatically opens the door. The front and rear doors are interlocked and cannot be opened simultaneously;

5. After the equipment arrives at the factory, make holes in the wall according to the size of the equipment;

6. It has disinfection and sterilization functions.

Technical Process:

1. After the workers place the materials on the air shower unit platform, the auxiliary flipping device flips the materials and removes the outer packaging;

2. After removing the outer packaging, the worker pushes the material forward. When the air shower unit senses the material, the left door opens and the roller begins to rotate;

3. At this point, the worker continues to push the material forward. When the material enters the air shower room more than halfway, it can be conveyed forward through the roller drive, and the worker does not need to push the material anymore;

4. At this time, when the air shower unit senses that there is no material on the left side, the left door will automatically close;

5. When the air shower unit senses the incoming material on the right side, the door on the right side opens and transfers the material to the right side; And transmit the signal to the next workstation, indicating the arrival of materials;

6. When the air shower unit senses that there is no material on the right side, the door on the right side closes;

7. The left and right two interlocks are both automatically completed.

Technical Features:

The air shower unit is made of stainless steel and equipped with centrifuge fans, primary and HEPA air filters, and conveyor belts. It has the characteristics of beautiful appearance, compact structure, easy maintenance, and simple operation. It uses high-speed clean airflow to blow and remove dust adhering to the surface of the packaging bag. Its nozzle can be adjusted to effectively remove dust and prevent external pollution from entering the clean area.