Detail:

Product introduction

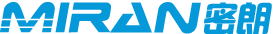

The purpose is to define an air particle detection system and record the actual presence of air particles in key areas during continuous production, to detect the environment and clean room air conditioning, and to automatically, continuously, and accurately monitor and record the distribution of particles and quantity levels in the air, and display them in the form of data reports in front of end users. Miran is a professional dust particle online monitoring system product integrator and a system installation and service partner of LightHouse in China, providing full service from system solution and design, product ordering, system installation, system verification, and after-sales Miran has many years of experience in project implementation and verification, including air particle counting, air molecule pollution, temperature and humidity, air speed, differential pressure, etc., with numerous domestic project cases and involvement in overseas markets.

Technical Description:

1. The particle counter adopts the American brand Lighthouse;

2. Adopting dual channel monitoring of 0.5um and 5um, with a flow rate of 28.3 L/minute;

3. External vacuum pump, one for backup and one for use, automatic or manual switching, can remotely start/stop the vacuum pump work;

4. Use a vacuum sampling tube with an internal conductive film specifically designed for cleanrooms imported from the United States;

5. The industrial controller adopts SIEMENS or BECKHOFF products, real-time industrial bus and real-time Ethernet technology;

6. Sound and light alarm system, which can provide sound or visual alarm signals, and can be equipped with color industrial touch screens for control clients;

7. The entire software system is designed as a closed LAN system that complies with the 21-CFR-11 standard;

8. Scalable online display and monitoring of temperature, humidity, pressure difference, air speed and other data;

9. Compatible with Windows 2000 and XP systems;

10. Can connect to Ethernet network;

11. RJ45 Ethernet port power supply mode (POE) can be used;

12. Data display with multiple modes;

13. Support Windows multi window and email functions;

14. It can display in real-time and search for data in various formats such as status, graphics, events, SPC diagrams, and user device layout diagrams. The interface can be displayed in either Chinese or English;

15. The provided solution complies with FDA or EU regulations on GMP;

16. Particle monitoring sensors do not require daily maintenance and cleaning, and can provide calibration services;

17. Provide verification files and verification services.

System components:

1. Particle online sensing system

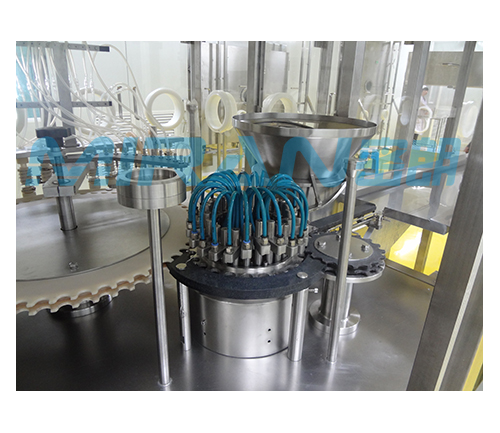

2. Online sampler for planktonic bacteria

3. Vacuum system

4. Alarm system

5. Real time monitoring software system

6. Install accessories

7. Project validation and training

8. After-sales service