Detail:

Product introduction

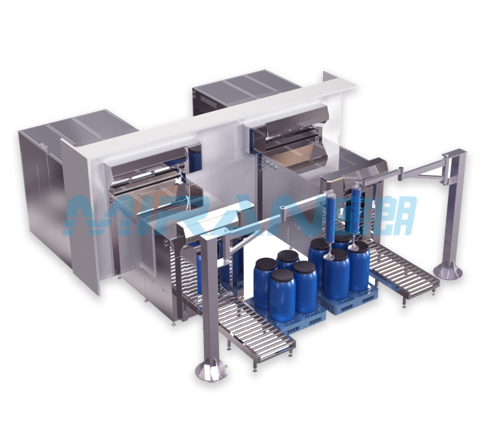

The Miran automatic sampling line equipment is mainly used in clean areas to complete the feeding -sampling-discharging steps in an automated manner through material handling, conveying, and blowing.

Product model: MIT-ASS-01

Process flow: The suction crane completes material handling, using an automatic control system speed regulation mechanism and a transmission system to push materials. During this process, the materials are blown and buffered, and then transported to the sampling and weighing room to achieve material transportation and sampling. The automatic transmission system discharges the material when it is transported back.

System components:

1) Suction crane

2) Sampling room platform

3) Airlock or air shower room

4) Automatic transmission system

5) Automatic rolling shutter door system

6) Sampling and weighing room

7) Composition of automatic control system

Operation steps:

1) Material tray to sampling and weighing room:

Vacuum elevator→Roller conveyor A→Front rapid rolling shutter door→Logistics air shower room→Rear rapid rolling shutter door→Roller conveyor B→Rear rapid rolling shutter door→Sampling room

2) Sampling and weighing room to material tray:

Vacuum elevator←Roller conveyor A←Front rapid rolling shutter door←Logistics air shower room←Rear rapid rolling shutter door←Roller conveyor B←Rear rapid rolling shutter door←Sampling room