Detail:

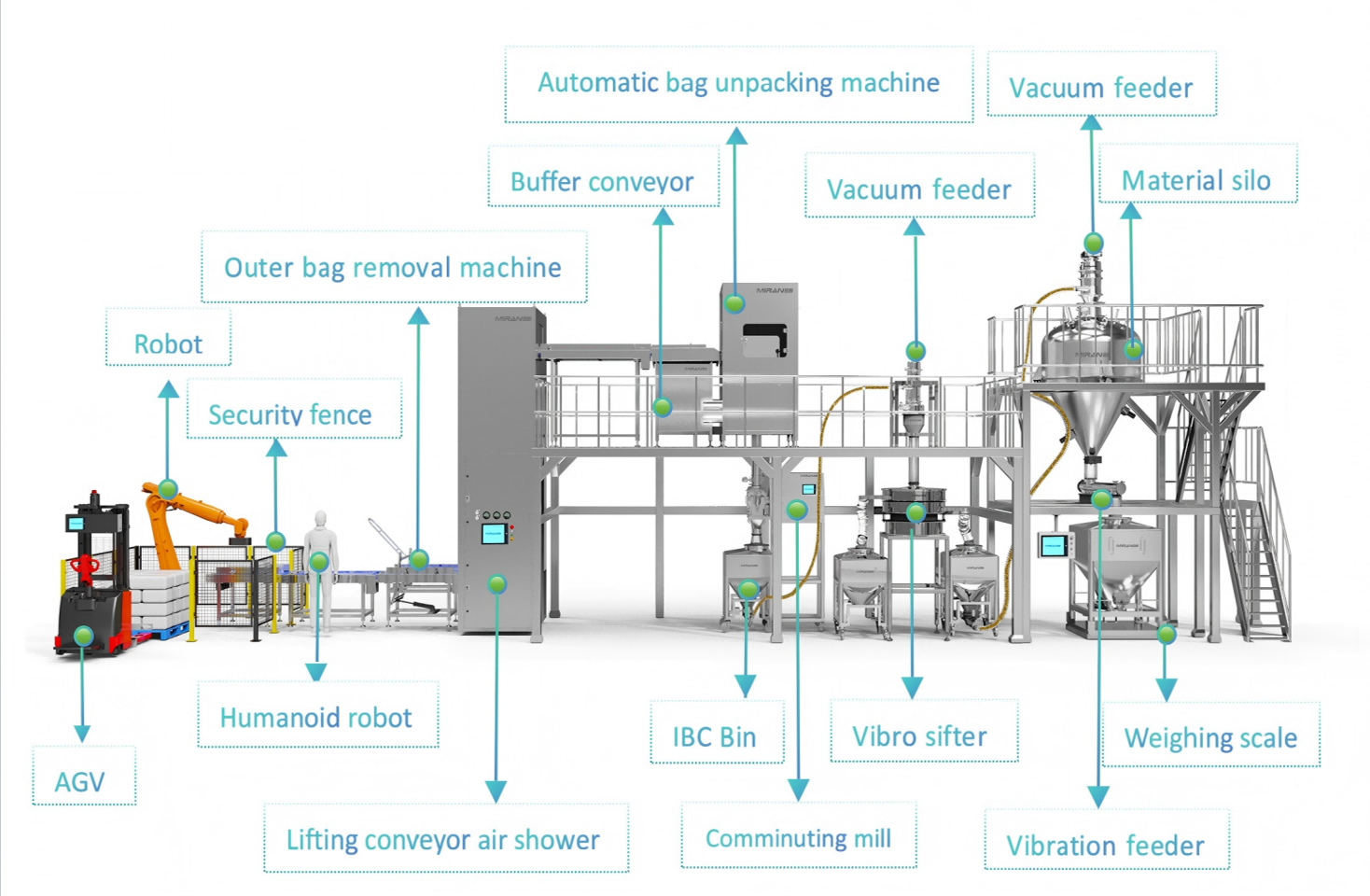

Description and Process Features of the Powder and Solid Material Pretreatment System

The powder and solid material pre-treatment system is a modern material handling solution that integrates automation, intelligence, and hygienic safety design. It is specifically developed for the pre-treatment processes of powder and solid raw materials in industries such as pharmaceuticals, food, and chemicals. The system follows a core process flow of "AGV transfer → robotic palletizing removal → outer packaging removal → air shower purging, UV sterilization, lifting, and conveying → hygienic automatic unpacking and feeding → crushing → sieving → temporary storage, metering, and batching", achieving full - process automated processing from raw material entry to precise batching. This significantly improves production efficiency and quality controllability while meeting high - standard hygiene requirements such as GMP/FDA.

System Features

1.The entire system enables automated, continuous, and enclosed production. It is modularly combined, offering high flexibility.

2.It reduces personnel and manual operations, minimizing human errors caused by manual handling.

3.It helps avoid confusion and errors, preventing contamination and cross - contamination.

4.It optimizes the logistics route.

5.It ensures accuracy and safety during the material transmission process.