Detail:

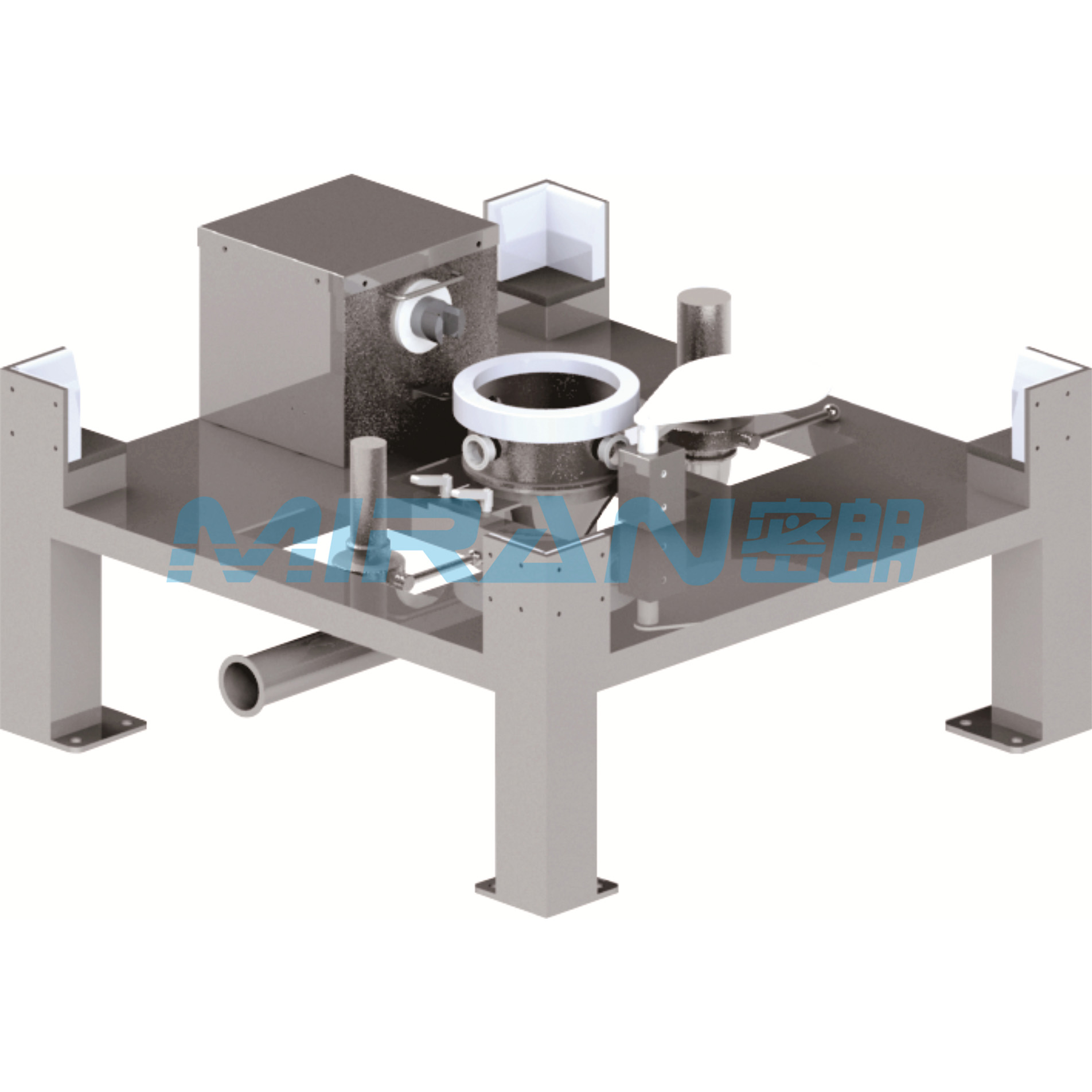

1. Product Introduction:

The discharging station equipment is used to assist in the discharging of IBC material bins, such as mixing machines, wet granulation lines, and sol tank feeding, etc. Place the IBC material bin on the discharging station, position the bin accurately with the positioning block, automatic closed docking of the discharge port, and match the valve opening mechanism with the valve head of the material bin. After receiving the production instruction, the blanking valve can be automatically opened, and the materials can be conveyed by vacuum or vertically dropped to feed the downstream equipment.

2. Product Advantages:

1) Inflatable seal ensures better sealing and no dust leakage;

2) Parts that come into direct contact with materials, with an easily detachable design for easy cleaning;

3) Equipped with an automatic dust cover to protect the feeding port from contamination when the equipment is in an empty state;

4) Equipped with a vibrating air hammer device to prevent material bridging inside the material bin;

5) Specially designed valve opening mechanism can be configured, with stronger valve opening reliability and higher tolerance rate;

6) It can cooperate with the air purging function to purge the discharge valve before the bin charging is completed and leaves.

3. Technical Parameters:

1) Equipment model: XLZ-01

2) Equipment size: L1100*W110*H600(± 50)mm, (can be customized according to the material bin)

3) Power conditions: 220V, 50Hz

4) Air source conditions: 0.4~0.6Mpa

5) Capacity output: 300~5000kg/h

6) Material: main body SUS304 or 316L (selected according to the URS)