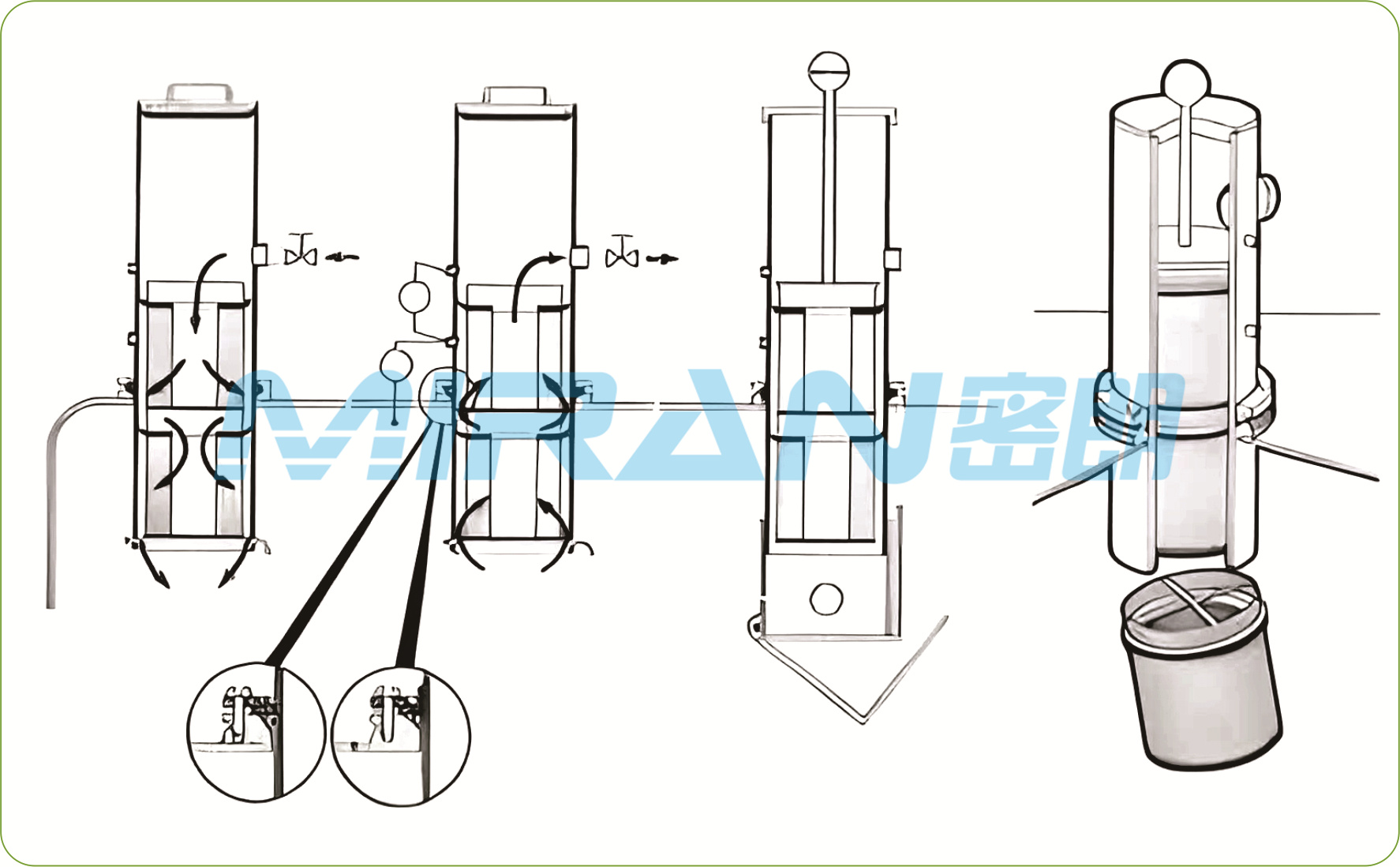

Detail:

Product introduction

In the production process of pharmaceuticals, such as key processes such as the filling of sterile pharmaceuticals and the sub-packaging of powder injections, or negative pressure protection isolation systems, sterility inspection isolation systems, etc., PUSH PUSH filtration technology can be used to filter the substances entering the production area. The air serves as an exhaust filtration system to remove microorganisms, dust and other impurities, prevent medicines from being contaminated, and protect the safety of operators and the surrounding environment. Provides assurance of sterile production and isolator system protection. PUSH-PUSH technology takes maintenance convenience into consideration. Its shell usually adopts a plug-in structure design that is easy to disassemble and install. When the filter reaches the end of its service life and needs to be replaced or needs cleaning, the operator only needs to insert the new filter element and simply push out the old one under the protection of a PVC bag (or high temperature bag). The filter element can be replaced without complex tools or professional maintenance skills, greatly reducing maintenance costs and downtime. This technology is widely used in biopharmaceuticals, chemical industry, electronics, food, automobile manufacturing and other fields.