Detail:

Product introduction:

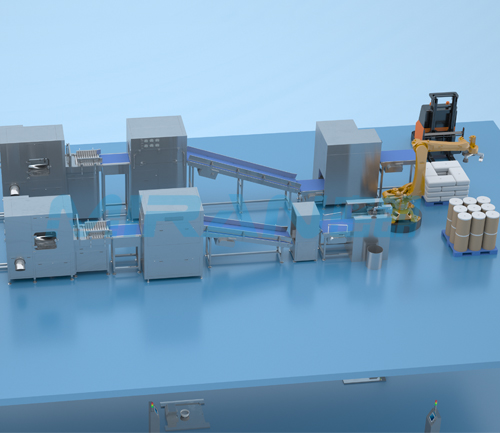

The intelligent production system for front-end solid preparations developed by Miran is suitable for the pharmaceutical, chemical, food, and new energy production fields. It is suitable for batch continuous production of bulk materials, reducing personnel operations. The system has a high degree of integration and automation, and can achieve the full line automation operation of raw material packaging from warehouses to process production equipment. It can realize automatic scanning, automatic disassembly (removal of outer barrels), automatic coding, internal packaging air shower dust removal and disinfection, online weight inspection, automated unpacking and feeding process with unmanned operation throughout the entire process. Maximizing intelligent production, improving production efficiency, reducing personnel costs, enhancing the level of intelligent production, and avoiding errors. It can achieve unified centralized control of the entire production line, with a high degree of intelligence, effectively reducing personnel participation, reducing pollution, and improving production efficiency.

Main Components:

1) Power assisted robotic arm

2) Conveyor belt

3) Barrel removal machine (bag removal machine)

4) Air shower equipment

5) Weighing and inspection equipment

6) Automatic unpacking and feeding machine

7) Sieving machine